Prefabricated

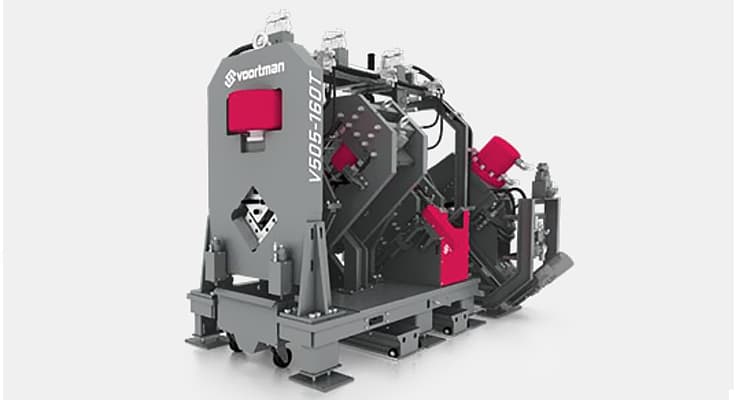

Are you looking to find reliable, high-quality machines that will help with your structural constructions? Our structural fabrication machinery will guarantee that you get the best results in beam and plate fabricating. These machines include angle masters and beam drill lines.